THEOREM 3

Ferromagnetic materials have a magnetic resistance 100 to 1000 times smaller than that of air or non-magnetizable materials!

In simple terms, it can be assumed that the field lines seek the path of least resistance, thus running in ferromagnetic material if possible.

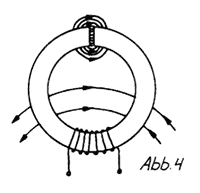

This can be demonstrated, among other things, on a closed iron ring to which a coil has been applied (fig. 4). Despite the very asymmetrical coil arrangement, most of the field lines generated by the coil run in the iron ring. If this closed path is interrupted in ferromagnetic material, the field lines must bridge part of this path in air. At this point of separation, a strong stray field is created, which means that the field lines exit the ferromagnetic material on one side of the defect and re-enter on the other side. However, this means the formation of magnetic poles.

Basic principle of magnetic particle testing

If fine iron powder is now scattered over this area of the ring, it will accumulate at the defective spot, because it is attracted by these magnetic poles, i.e. by the scattered field. The field lines again find a way through the powder particles through ferromagnetic material and hold the powder particles at this place.

Since the field line path in the rest of the iron ring is undisturbed, therefore, when the entire ring is sprinkled with iron powder, a powder accumulation remains only at the defective point with the existing stray field. Since the area of the scattering field is considerably wider than the defect, such a "powder bead" can be easily perceived.

This phenomenon already represents the basic principle of magnetic powder testing: If the course of magnetic field lines in ferromagnetic material is disturbed, a stray field is produced, which can be detected with the aid of iron powder. This is also successful in the case of defects with a very small width, which means that even the finest material separations, such as cracks or similar, can be detected.