Today, anyone who sits down in an airplane, car or other means of transportation, or uses an elevator, expects flawlessly functioning technology. Every day, our lives depend several times on the safe functioning of the mechanized and automated world that surrounds us. Often, we do not even think about a possible risk, but trust completely the responsible designers and manufacturers of the respective products, according to the motto "they surely know what they are doing"!

This trust is well justified, because vital parts, which are declared to be safety parts, have to pass extensive tests before they take over the safety for human lives according to their function. For such tests, which have become indispensable in the field of nuclear power plants, for example, different test methods are used today, depending on the problem, which together belong to the group of "non-destructive testing".

Magnetic particle testing is of particular interest in this context. It can be used to detect gap-like material separations such as cracks in magnetizable material. A crack, no matter how fine, in a highly stressed component can easily lead to fatigue failure and thus become the cause of a disaster.

The following article aims to illustrate the processes involved in magnetic particle testing to the reader in simple terms and illustrations and to provide information on the most important physical principles. The text has been deliberately kept simple, because it is intended to reach readers who have no knowledge in this field. For the specialist, too, this explanation is sure to provide an interesting source of information.

Magnetism AND ITS APPLICATION IN MAGNETIC PARTICLE TESTING

As the term "magnetic particle testing" already makes clear, this method exploits magnetism, i.e. the workpieces to be tested, or generally speaking, the test sections concerned, are magnetized. With small permanent magnets, it is easy to determine that there are materials that are attracted by such a magnet, while others experience no force at all. This results in a distinction between magnetizable and non-magnetizable materials. From this it can already be deduced that not all materials can be detected with magnetic particle testing, but only those which are magnetizable, so-called "ferromagnetic materials" (ferromagnetic = magnetic like iron).

Ferromagnetic materials

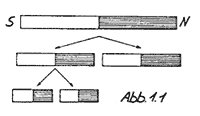

For easier understanding, one imagines the ferromagnetic materials as a composition of tiny bar magnets, the so-called "molecular magnets". The commonly known bar magnets always have a north and a south pole at their two ends. If you cut such a bar magnet in the middle, you will get two complete smaller bar magnets with the two mentioned poles.

Again, these newly obtained bar magnets can be divided into two complete magnets each. Mentally, one can continue this game until the size range of the molecular magnets is reached.

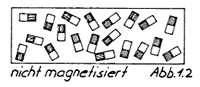

Many of these molecular magnets joined together in a disordered direction form the ferromagnetic material, which is outwardly magnetically neutral.

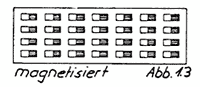

If a strong external magnetic field is now generated, the molecular magnets orient themselves in a common preferred direction corresponding to the external field, after which the magnetic forces of all of them act together and thus become measurable. Consequently, the material is now magnetized. From a physical point of view, molecular magnets are crystalline regions of the material with the same magnetic moment (spin direction of the electrons) of the individual atoms.

Magnetization

Now the essential question arises: How to generate an external magnetic field to achieve the effect of magnetization described above (alignment of molecular magnets)?

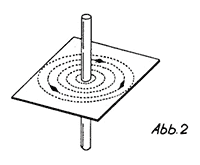

The basic answer to this question was given by the physicist Oersted, who first discovered in 1820 that every current-carrying conductor is surrounded by a magnetic field. This circular field can be demonstrated by a simple experiment: For example, you put a copper rod through a piece of cardboard and sprinkle fine iron powder on it. If current flows through the copper rod, all the powder particles arrange themselves in concentric rings, or lines, around the conductor through which the current flows. The lines that appear here represent the course of the field and are generally referred to as lines of force or field lines, which always have a self-contained course.