THEOREM 5

Field line direction and fault direction must be transverse to each other!

If, as is very often the case, the fault position is unknown, magnetization must be carried out in different directions.

If the two directions of magnetization are approximately 90 degrees to each other in this case, all defect directions can be detected because one of the two fields is guaranteed to be in the appropriate angular range to the defect direction.

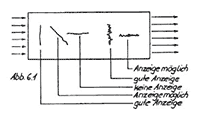

The above-described regularity sometimes seems to be refuted in practice, because defects are suddenly detected which have the same direction as the magnetic field lines. In this case, the material is usually coarse-grained and cracked along the grain boundaries (intergranular crack). This defect in turn has a lot of transverse components to the field direction, resulting in a stray field (fig. 6.1).

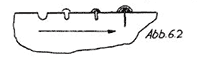

However, not only the defect direction, but also the defect geometry is an essential factor in the formation of a stray field. Fig. 6.2 shows how the intensity of the stray field increases with increasing "slenderness" of the defect. Thus, the ratio of defect depth to defect width is also important, and for sufficient results this ratio should be > 5.

However, not only the defect direction, but also the defect geometry is an essential factor in the formation of a stray field. Fig. 6.2 shows how the intensity of the stray field increases with increasing "slenderness" of the defect. Thus, the ratio of defect depth to defect width is also important, and for sufficient results this ratio should be > 5.

Magnetization methods

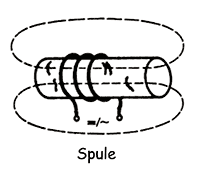

In order to achieve, as mentioned, different field line directions during magnetization, different magnetization methods are available, which are specified by different device types.

Particularly in stationary systems, two or more such systems are sometimes combined with each other to enable fast and thus rational crack detection. However, when several systems are used simultaneously, the physical laws that make this possible must be observed. However, this is the responsibility of the manufacturer, who designs equipment and systems accordingly.

The magnetization methods usually used are listed in the standard "DIN 54 130" and are divided as follows:

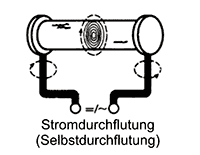

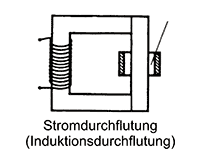

| Current flooding |  |

|---|---|

|

|

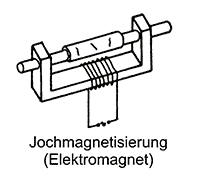

| Yoke magnetization (by means of permanent or electromagnet) |

|

| Magnetization with current carrying conductor |  |

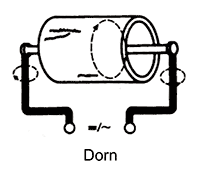

"Auxiliary flooding" by means of mandrel "Auxiliary flooding" by means of mandrel |

Basic ideads about magnetic particle testing as PDF document (6.2 MB).